Worm gear motors are a type of gear motor widely used in various industrial and commercial applications. They offer unique advantages but also come with certain limitations. In this blog post, we’ll explore the pros and cons of worm gear motors to help you understand when they’re the right choice for your application and when you might want to consider alternative options.

Pros of Worm Gear Motors:

1. High Gear Reduction Ratio:

- Worm gear motors provide high gear reduction ratios, making them suitable for applications that require high torque output at low speeds.

- The screw-like motion of the worm gear allows for significant torque multiplication without the need for large gears.

For example, the mininum gear ratio is 65:1 for micro worm geared DC motor HT-WOG34 series, and 39:1 for big size DC worm gear motor HT-WOG58 series, while the gear ratio could be as small as 4:1 for most of planetary gear motors, like 22mm planetary gear motors, 28mm planetary gear motors, 36mm planetary gear motors.

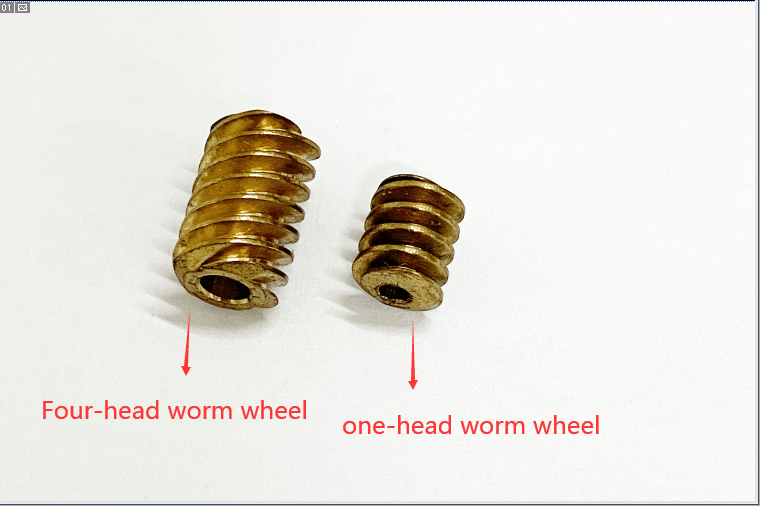

2. Self-locking Feature:

- One of the key advantages of worm gear motors is their self-locking capability.

- When the motor is not energized, the friction between the worm and worm wheel prevents the load from back-driving the motor, providing inherent braking and preventing reverse motion.

- Self-locking capability depends on the head number of worm wheel. If worm wheel only has one head, the self-lock capabity is 100% guaranteed, if the worm wheel has 4 heads, this worm gear motors bascially lose the self-lock capablity.

3. Compact Design:

- Worm gear motors have a compact design, making them suitable for applications with limited space.

- Their compact size allows for easy integration into machinery and equipment where space is at a premium.

4. Quiet Operation:

- Compared to some other types of gear motors, worm gear motors tend to operate quietly.

- The sliding contact between the worm and worm wheel produces minimal noise, making them suitable for noise-sensitive environments.

Cons of Worm Gear Motors:

1. Limited Efficiency at High Speeds:

- Worm gear motors are not well-suited for high-speed applications due to the sliding contact between the worm and worm wheel.

- The friction generated at higher speeds can lead to reduced efficiency and increased heat generation.

- Because of sliding conact, the transmission efficiency will change when loaded torque is different. So for worm gear motors, the efficiecy would vary.

2. Backlash and Precision Issues:

- Worm gear systems typically exhibit higher levels of backlash compared to other gear systems.

- This backlash can result in reduced precision and accuracy, making worm gear motors less suitable for applications that require tight tolerances.

3. Limited Reversing Capability:

- Worm gear motors are not ideal for applications with frequent reversing loads.

- The sliding action between the worm and worm wheel can cause additional wear and stress on the gear teeth, reducing the motor’s lifespan.

4. Potential for Overheating:

- The sliding contact between the worm and worm wheel can generate heat, especially under heavy loads or prolonged operation.

- Proper cooling and lubrication are essential to prevent overheating and premature wear of the motor components.

Conclusion:

While worm gear motors offer several advantages, including high gear reduction ratios, self-locking capability, compact design, and quiet operation, they also have limitations that need to be considered. Understanding the pros and cons of worm gear motors is crucial for selecting the right type of motor for your specific application. In situations where high-speed operation, precision, or frequent reversing loads are critical, alternative gear motor options such as spur gear motors or planetary gear motors may be more suitable. However, for applications that require high torque output, compact size, and self-locking features, worm gear motors remain a popular choice.

You can reach out to Hotec Motor any time for proper gear motor solution for your products.