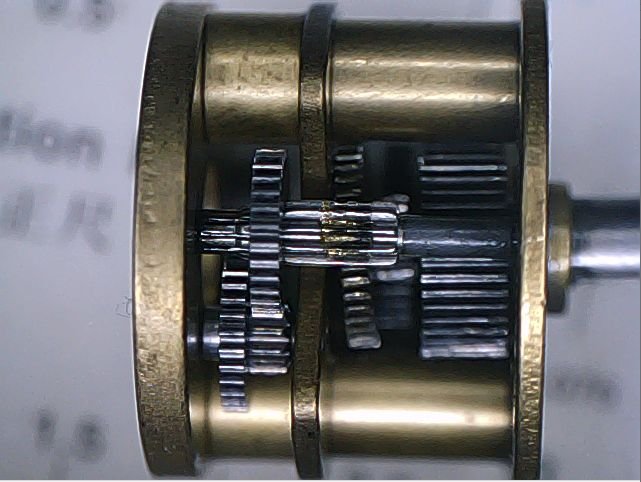

In today’s rapidly evolving technological landscape, the demand for DC gear motors is soaring. From AI-driven machinery to IoT-enabled devices, these compact powerhouses are becoming ubiquitous in various applications, promising seamless automation and precise control. Whether you’re a seasoned engineer crafting cutting-edge products or an enthusiast tinkering with DIY projects, understanding the critical aspects of DC gear motor usage is paramount. Here, we unveil the three essential considerations to ensure optimal performance and longevity:

- Avoid Motor Stalling:

Stalling occurs when a gear motor is forced to stop abruptly due to too much load or system jamming, causing the speed to drop to zero. This situation subjects the gear motor to high torque and current, known as stall torque and stall current, respectively. Stall torque can immediately break gears inside the gearbox, while stall current may lead to the burning out of the DC motor. To prevent damage and prolong the lifespan of your gear motor, it’s crucial to avoid stalling whenever possible. If stalling is unavoidable in your application, reach out to our engineering team for tailored solutions.

- Be Mindful of Motor Reversals:

Sudden reversals, especially at high speeds, can have detrimental effects on gear motors. When a motor undergoes an abrupt direction change without sufficient dwell time, the rotator and gears continue rotating forward due to inertia. This sudden reversible rotation can cause severe impacts, leading to broken gears and significant sparking, ultimately shortening the gear motor’s lifespan. If your application necessitates frequent reversals, ensure they are executed gradually to mitigate potential damage.

- Limit Frequent Motor Start-Ups:

Frequent start-ups impose considerable wear and tear on DC gear motors, accelerating their degradation and reducing their longevity. Start-up generates starting torque and current , equivalent to stall conditions, hastens the wear on the motor’s brushes and commutator, ultimately diminishing its lifespan. Minimize the frequency of start-ups whenever possible to enhance the reliability and longevity of your gear motor. If frequent start-ups are unavoidable in your application, rely on our engineering expertise to develop solutions that mitigate wear and improve reliability.

- Avoid Overloading the Gear Motor:

Regularly monitor the load conditions to ensure that the motor operates within its specified capabilities. Overloading the motor beyond its capacity can subject it to mechanical stress, increased wear, overheating, and potential failure. By preventing motor overload and ensuring it operates within its safe operating range, you safeguard your gear motor and prolong its lifespan.

In Conclusion:

Understanding these fundamental principles is paramount for maximizing the performance and longevity of DC gear motors in your applications. By avoiding motor stalling, mindful reversals, limiting frequent start-ups, and preventing motor overload, you can optimize the efficiency and reliability of your gear motor. Should you encounter unique challenges or specialized requirements, our experienced engineering team is ready to provide customized solutions. Embrace these insights to make use of DC gear motors at maximum efficiency point in your projects and applications.