In today’s industrial and automation environments, DC gear motors are essential components powering a wide range of systems — from factory equipment and robotics to medical devices and smart IoT machinery.

Their ability to deliver high torque, precise control, and compact design makes them indispensable for engineers and system designers.

To ensure long-term reliability and optimal performance, it’s vital to understand how to operate, protect, and maintain DC gear motors properly.

Below are four key engineering practices to help you maximize your motor’s efficiency and service life.

1. Prevent Motor Stalling

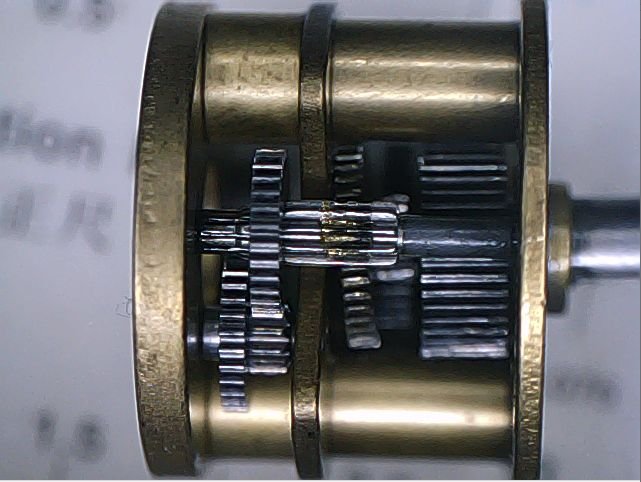

Motor stalling happens when the output shaft stops rotating due to excessive load or system blockage. During this state, torque and current increase dramatically — referred to as stall torque and stall current.

Why Stalling Is Harmful

- Causes gear tooth breakage or deformation

- Overheats windings and burns out motor coils

- Reduces overall efficiency and lifespan

Engineering Recommendations

- Integrate current-limiting protection in motor driver circuits

- Use thermal sensors to prevent overheating

- If stalling is unavoidable, consult our engineering team for customized gearbox and motor solutions

2. Manage Direction Reversal Properly

Frequent or abrupt direction changes at high speed can severely stress the gears and rotors.

The inertia of moving parts causes impact loads that can damage internal components or create excessive noise.

Best Practices

- Add a delay ( 1-2 seconds) before reversing direction

- Use soft-start / soft-stop control to reduce impact torque

- Employ PWM or motor drivers with dynamic braking capability

- Ensure the gear motor is rated for bidirectional operation

Smooth direction changes protect both gears and electronics, resulting in quieter and more reliable motion.

3. Limit Frequent Start-Ups

Every motor start-up generates a surge current similar to a stall condition.

Repeated start-stop cycles accelerate brush wear, heat buildup, and reduce motor lifespan.

How to Reduce Start-Up Stress

- Use soft-start controllers or PWM ramp-up functions

- Minimize unnecessary start-stop operations

- Consider brushless DC (BLDC) motors for high-frequency applications

4. Avoid Overloading the Gear Motor

Continuous overloading beyond rated torque or speed leads to mechanical fatigue, overheating, and failure.

Engineering Guidelines

- Select a motor running at max efficiency powith with your desired speed and torque

- Monitor current, voltage, and temperature under real operating loads

- Maintain proper lubrication and alignment of mechanical parts

- Prevent prolonged operation at maximum rated torque

Keeping the motor within its safe operating range ensures reliability and reduces unplanned downtime.

Conclusion

Understanding and implementing these four engineering practices will significantly improve the performance, reliability, and longevity of your DC gear motors:

- ✅ Prevent stalling

- ✅ Manage reversals carefully

- ✅ Limit frequent start-ups

- ✅ Avoid overloading

At HOTEC MOTOR, our engineering team provides customized motor and gearbox solutions tailored to your torque, speed, and duty cycle requirements.

If your project involves precision motion control or demanding industrial environments, contact us for expert guidance and product recommendations.