In the world of smart technology, precision engineering often makes the difference. Our recent collaboration with a European customer developing innovative electric blinds is a testament to this. While they were initially impressed with Maxon’s brushless DC gear motors, the need for customization led them to our doorstep, where flexibility, affordability, and top-notch performance converged.

The Initial Impression: Maxon’s Brushless DC Gear Motors

Our European customer was in the midst of developing smart blinds of varying sizes. In their initial prototypes, they tested Maxon’s brushless DC gear motors and were highly satisfied with their performance and low noise levels. So, what prompted them to explore other options? The answer lies in the customization capabilities offered by Chinese manufacturers – a cost-effective and flexible approach that could expedite the launch of their electric blinds, making them more competitive in the market.

Setting the Bar: Performance Specifications

The specifications our customer sought for their smart blinds were precise, and the gear motors needed to meet these expectations:

Performance Requirements:

- Nominal Voltage: 6V

- Continuous Torque: 23kg.cm

- No Load Speed: 30 RPM

- On Load Speed: 22 RPM

- Output shafts: Parallel to motors.

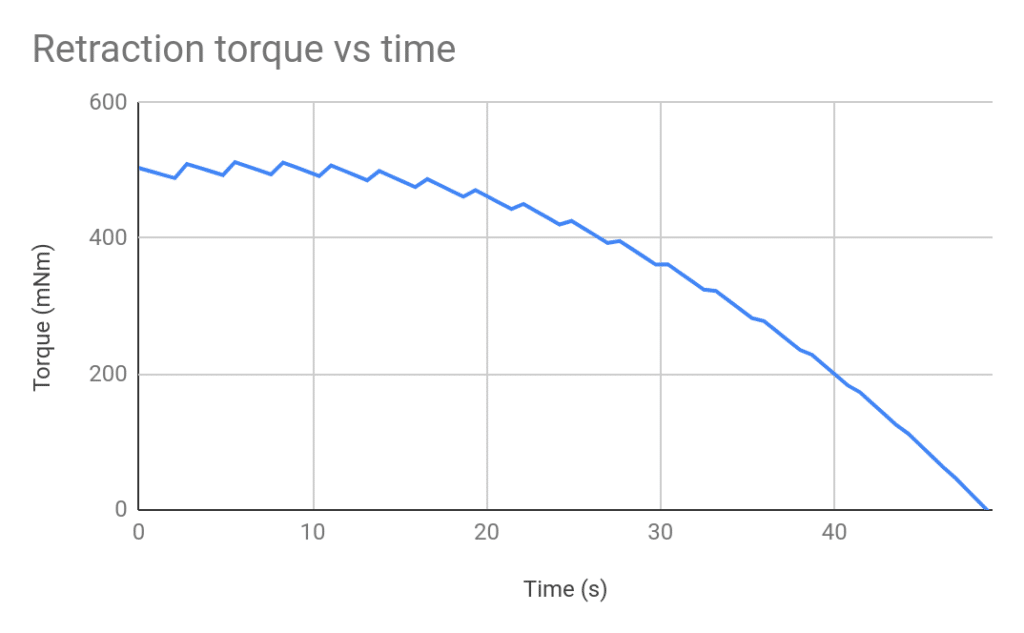

Understanding the Application: Lifting and Lowering Curtains

The gear motors would play a crucial role in lifting and lowering the curtains. This task presented dynamic challenges as both the force and lever changed throughout the operation, causing variations in the required torque. To provide a clearer picture, please refer to the accompanying graph.

- Duty Cycles: 30 seconds per duty cycle, with a maximum of 8 duty cycles each day

- Life-Cycle Expectation: 45,000 duty cycles, totaling about 500 hours

- Output Direction: Both clockwise (CW) and counterclockwise (CCW)

- Potential Stall: In the application, motor stalling was a possibility. To safeguard the gear motors, the customer implemented current limitations.

Finding the Right Solution: Brushed Gear Motors

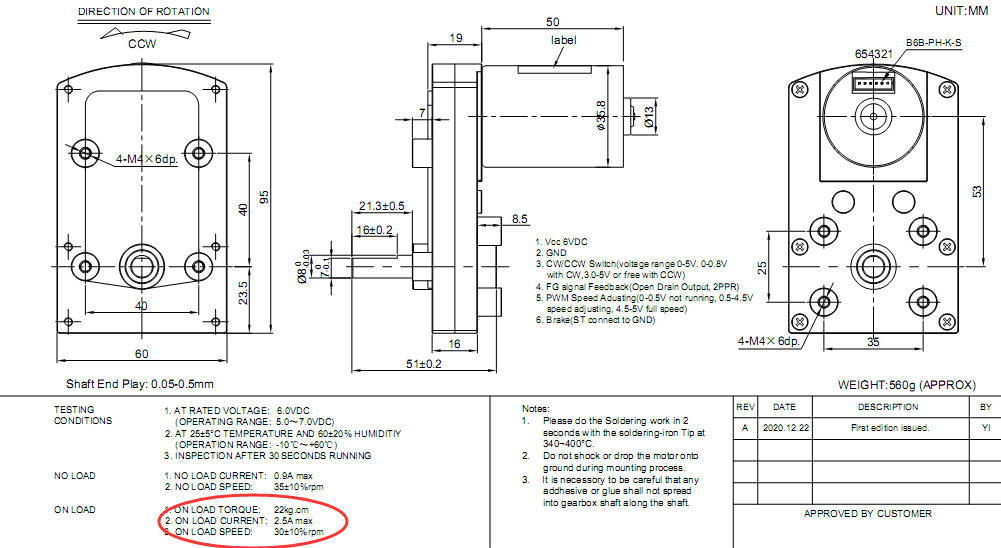

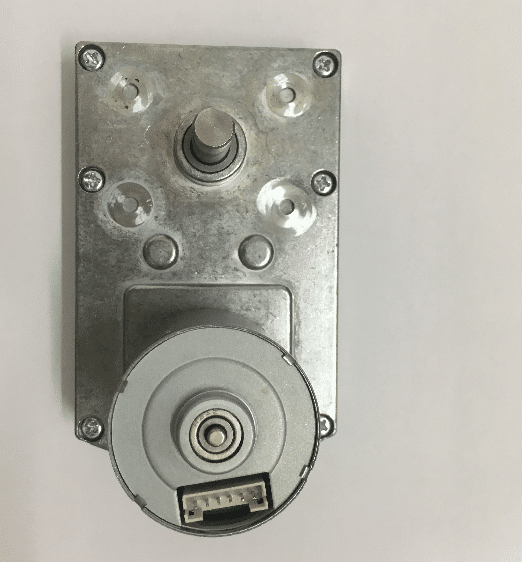

Following a thorough evaluation by our engineering team, it was determined that brushed gear motors were more than capable of fulfilling the requirements, eliminating the need for the more expensive brushless alternatives. The customer was receptive to this solution and expressed a desire to test both brushed and brushless samples. As a result, we recommended HT-WOG58C worm gear motors and HT-COG95C flat gearbox motors, both equipped with parallel shafts. HT-WOG58C worm gear motors were rejected because of mounting space. So, HT-COG95C brushed and brushless gear motor samples were made and sent for customer’s test.

The Testing Phase: Refining for Lower Noise

In the initial sample testing, our gear motors operated successfully in the customer’s prototypes. However, they observed that our motors produced more noise compared to Maxon’s, a critical factor in blinds and curtains. Additionally, given their patent design, the customer pivoted towards brushless motors.

Test Data Collection and Analysis:

First, per the customer’s test data, the maximum loaded current in their application is 900mA. Based on this, our engineers concluded that the maximum loaded torque requested in the customer’s application is 10kg.cm, not as high as the 23kg.cm the customer demanded. Please refer to attached datasheet:

Therefore, we helped the customer to correct the specifications and update them as below:

- Nominal Voltage: 6V

- Continuous Torque: 10kg.cm

- On Load Speed: 22 RPM

Lower Noise Gearbox Motor Solution:

HT-COG9C samples at the fist time were configured with 6V 6800RPM brushless motors and a 1:189 gear ratio. To reduce the noise, we adopted 6V 4000 RPM brushless DC motors to match a 1:162 gear ratio, to build new samples. Lower input speed and a lower gear ratio significantly improved the noise level. In addition, hybrid gearsets (a combination of plastic gears and metal gears) were used to mitigate the noise.

Customization for Efficiency

The journey didn’t stop at reducing noise; we also tailored the gear motors to match the customer’s specific requirements. This included removing unnecessary mounting holes and customizing output shafts, ensuring a seamless fit for their innovative blinds.

The Verdict: Lower Noise, Improved Performance

Upon testing the new samples, the customer was thrilled with the reduced noise levels, which even surpassed those of Maxon motors. This improvement would undoubtedly enhance the overall experience of their smart blinds.

Ensuring Longevity: Extensive Lifecycle Testing

In addition to field tests conducted by the customer, we performed lifecycle testing in our lab, simulating the motors’ work scenario in smart blinds. After 89,000 duty cycles, equivalent to approximately 2,711 hours, the gear motors continued to operate smoothly, exhibiting normal output speed, current draw, and noise levels. Upon concluding the lifetime test, we disassembled the gearboxes, finding gears, bearings, and shafts in excellent condition, indicating the potential for an even longer lifespan.

Conclusion: Transforming Smart Blinds with Customization

Our collaboration with this European customer underscores the power of customization in precision engineering. At HOTEC MOTOR, we’re dedicated to delivering tailored solutions that enhance innovation. For all your micro DC gear motor needs, trust us to transform your concepts into high-precision solutions that redefine smart technology.