Finding the right 24V DC gear motor with encoder can feel complex, especially when you consider the wide range of motor types, encoder options, and performance specifications available.

At HOTEC MOTOR, our goal is to simplify this process by helping engineers and technical designers identify the most suitable configuration for their projects.

Below is a practical step-by-step guide to help you choose the ideal 24V DC gear motor for your application.

Step 1: Determine the Type of Gear Motor

Different gear motor types are suited to different mechanical requirements. Understanding their characteristics helps you make an informed selection.

Common 24V DC Gear Motor Types

- Spur Geared Motors – Simple and cost-effective; ideal for applications requiring moderate torque and higher speed.

- Planetary Geared Motors – Compact, durable, and capable of high torque and precision, suitable for robotics, automation, and industrial equipment.

- Worm Geared Motors – Designed for low-speed, high-torque operation with the added benefit of self-locking capability.

- Flat Gearbox Motors – Space-saving and efficient for compact applications where design constraints limit motor size.

Engineering Tip:

If your application demands both high torque and compact design, a planetary gear motor typically offers the best performance-to-size ratio.

Step 2: Define Speed and Torque Requirements

While “24V DC gear motor with encoder” may describe a category, the ideal motor depends on how much torque and speed your application demands.

Ask yourself:

- ⚙️ What RPM (revolutions per minute) does your system need?

- 🧭 What torque must the motor deliver to move the load effectively?

Examples

- For high-torque, low-speed systems (e.g., conveyors or lifting mechanisms), a worm or planetary gear motor with a higher gear ratio is ideal.

- For high-speed, moderate-torque applications, consider spur or flat gearbox motors with lower gear ratios.

Pro Tip: Always maintain a safety margin — select a gear motor that can handle 20–30% higher torque than your expected load.

Step 3: Choose the Right Encoder

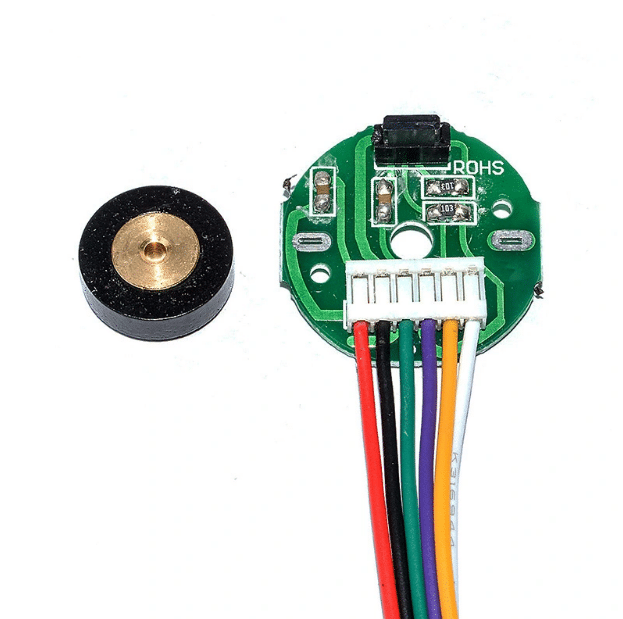

Encoders enable precise position and speed feedback, making them critical for automation, robotics, and motion control systems.

At HOTEC MOTOR, we offer a variety of magnetic and optical encoder configurations to fit your needs.

Standard Encoder Options

- Two-channel Hall sensor encoders with resolutions of 3 PPR, 7 PPR, or 12 PPR for various accuracy levels.

- Operating voltage: 2.5V–12V (with 5V recommended for stable signal output).

- Support for quadrature signal output for direction and speed detection.

If your application requires higher precision, we can modify the rear shaft to accommodate optical encoders or custom sensors.

Step 4: Consider Customization Options

Every project has unique requirements — customization ensures that your gear motor performs optimally in its operating environment.

Available Customizations

- Voltage Flexibility: All gear motors can be configured for 24V DC operation or other voltages as needed.

- Rear Shaft Modifications: Designed for encoder mounting or specialized couplings.

- Material & Grease Options: Adapt to environmental challenges such as high humidity, corrosion, or extreme temperatures.

- Wiring & Connector Options: Tailored to your system’s electrical interface and installation preferences.

Why Choose DC Gearbox

At HOTEC MOTOR, we go beyond selling motors — we provide engineered motion solutions.

Our technical team works closely with you from design to production, ensuring that every motor and gearbox combination meets your exact torque, speed, and control requirements.

Whether you need a custom planetary gear motor for consumer devices or a worm gear motor with encoder for industrial automation, we can help you find the perfect match.

Get Expert Support

Looking for the right 24V DC gear motor with encoder for your next project?

👉 Contact our engineering team today for personalized recommendations and detailed product specifications.