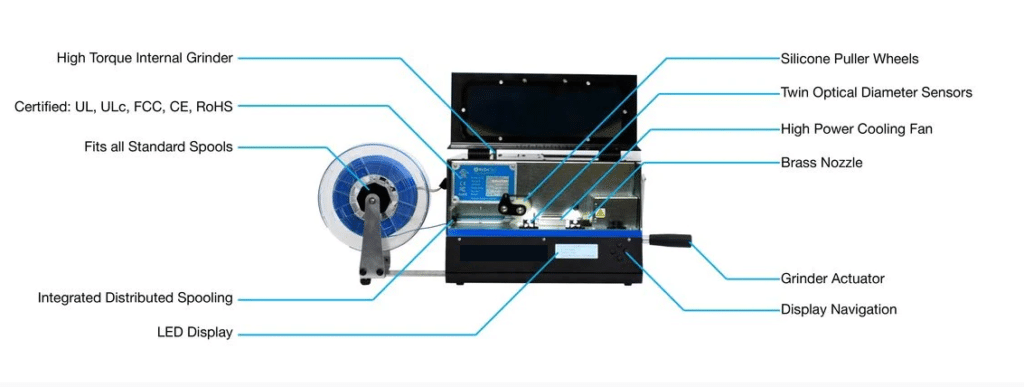

3D printing is a new technology that facilitates the creation of prototypes at a low cost. Filament is the necessary material for 3D printers. To reduce costs, filament extruders have emerged in the market. Today, we will introduce to you the DC gear motor solution for 3D filament extruders.

Work Scenario:

Duty cycle: In 3D filament extruders, the motors have to run for 8 hours continuously (NOT every day).

Lifetime expectancy: 2-3 years.

Output direction: ONLY CW

Stall: no stall. The customers have overload protection in their circuit in case of a stall.

Specification Requirement:

Nominal voltage: 12VDC

On-load speed: 7RPM

Rated torque: 100kg.cm.

After our engineering team’s evaluation, we recommended HT-FOG119B gear motors to the customer. HT-FOG119B are rectangular spur geared DC motors, with a maximum rated torque of up to 300kg.cm. It’s a high-torque DC gearbox motor solution at a low cost. It completely meets the customers’ specifications and applications.

Subsequently, we built samples using different configurations and materials to optimize the gear motor,to make it work better with customers’filament extruder. It proved that HT-FOG119B brushed gear motors are entirely suitable for the filament extruder after all tests are completed.

In some customers’ filament extruders, stepper gear motors are adopted. It depends on the customer’s product design.